Reference documents:

T6’s used in the evaluation

Some clarifications about terms used later.

Introduction – How 4Motion works in different driving situations

Pulling away or accelerating - measurement

Fast driving - measurement

Braking - measurement

Stopping - measurement

Good news. I fully agree with logic presented in the documentation and also verified the stated functionality on vans with 150kW/204PS engine on all DSG gears 1-7. Test vans (3) and (4).

Not so good news is that the above seems to be true only on DSG gears 1-4 on vans equipped with 110kW/150PS engine. Test vans (1) and (2).

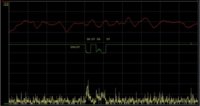

A sample from a 110kW/150PS DSG van (1) graphed: Symbology as in the first graph. Gears used marked in the picture. Note and compare speed delta (yellow at the bottom) with the first picture.

Manual gearbox

To be continued...

VW Self Study Programme SSP 561 –The T6 2016, which in chapter Power transmission (p.26) for details on 4Motion control logic refers to:

VW Self Study Programme 414 – 4MOTION with 4WD coupling generation IV. The document can be read and downloaded at SSP 414

Spesifics about 5th generation Haldex clutch from page 20 onwards in

VW Self Study Programme 515 – The Golf 2013 Running Gear and Four-wheel Drive Concept. ---> SSP 515

T6’s used in the evaluation

(1) MY16 T6 panel van T32 16” chassis LHD LWB Engine CXFA (04L 906 056 KF rev 3809) EU6 110kW/150PS DSG (SW:5220) 4Motion (SW:7620)

(2) MY18 T6 panel van T30 16” chassis LHD LWB Engine CXHA (04L 906 056 KE rev 3772) EU6 110kW/150PS DSG (SW:5301) 4Motion (SW:7620)

(3) MY17 T6 panel van T30 17” chassis LHD LWB Engine CXEB (04L 906 056 KN rev 3776) EU6 150kW/204PS DSG (SW:5302) 4Motion (SW:7620)

(4) MY18 T6 panel van T32 17” chassis LHD LWB Engine CXEB (04L 906 056 KN rev 3776) EU6 150kW/204PS DSG 4 (SW:5302) Motion (SW:7620)

During past two years in the van (1) three coupling pumps (V181) and two complete Haldex-clutches were “evaluated”.

Some clarifications about terms used later.

Terms clutch, coupling, Haldex-clutch, etc, all refer to the same coupling unit used in T6 4Motion models.

The term “Haldex-clutch degree of blockage” comes from VCDS measuring values, similar term is used also in VW garage testers. Value 0% means the coupling is open and no torque is transferred to/from rear axle. Value 100% means that clamping pressure at the clutch is at maximum and torque up to 2400 Nm can be transferred to/from rear axle.

Introduction – How 4Motion works in different driving situations

Pulling away or accelerating - measurement

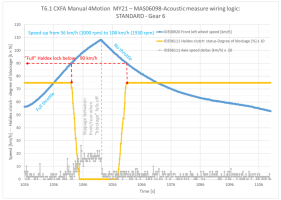

The measurement graphed below was just to measure actual control range mentioned above. General idea is that clutch clamping pressure/force is high at slow speeds and gradually decreases as speed increases (when accelerating).

Explanations.

- Time scale 20 seconds/division, full picture 200 sec.

- Red line - vehicle speed. Scale 0-100 km/h.

- Green line - Haldex-clutch degree of blockage. Scale 0% in the middle, full scale 50% (just to better show low values).

- Yellow line - measured speed difference between front and rear axle. Scale 0-5 km/h, so each horizontal line equals to 0.5km/h. Noisy curve at the bottom.

- Circle C – At steady cruising speed (90-100km/h), very low coupling, degree of blockage, 1-3%.

- Circle B – Note a speed delta between front and rear as vehicle is mainly front wheel driven running at steady speed - the rear wheels are almost just free rolling.

- Circle A – At full throttle very tight “preemptive” coupling, the coupling does not allow speed difference between front and rear axles (yellow line at the bottom).

- On the left at time stamp 25-75 sec, speed (red) from 0 km/h to 80 km/h, starting at first notch on the left. – normal, easy pull away - preventive “reasonable level” of coupling (green).

- Before full throttle pull away – quite hard braking to stand still at time stamp 110-120 sec, some slippage (delta spike (yellow)).

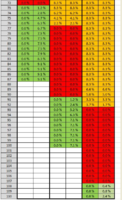

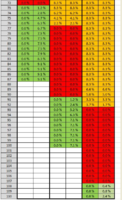

From the graph/data above only theportion of full throttle pull away graphed to depict degree of blockage (Haldex-clutch coupling) vs. vehicle speed in the graph below.

Proves the general idea that clutch clamping pressure/force is high at slow speeds and gradually decreases as speed increases.

Note that in the above the blockage is the absolute maximum blockage as engine is using low gears to gain more torque at wheels through gearing ratio. Thus the maximums above are from gears 1-4.

On higher gears degree of blockage needed is less. For example on 6th and 7th gears at speed of 80 km/h max blockage achieved is about 10% (about half of the absolute maximum). On the 5th gear slightly more 13%, etc.

Fast driving - measurement

The measurements also verified the behavior and control range at “fast driving” – degree of blockage/coupling from 0% (engine braking) up to predetermined value (as in the graph above). An example at circle “C” in the first graph.

Braking - measurement

Verified – disengages with slightest touch of brake. Except at standstill, then the coupling is prepressurized thus giving no-slip set off. Degree of blockage/coupling observed is about 12% at standstill when foot on brake, idling, gear D1. Goes immediately high up when throttle is applied.

Stopping - measurement

Actually means engine braking (coasting function not yet verified). The clutch is disengaged - degree of blockage/coupling is 0%.

Good news. I fully agree with logic presented in the documentation and also verified the stated functionality on vans with 150kW/204PS engine on all DSG gears 1-7. Test vans (3) and (4).

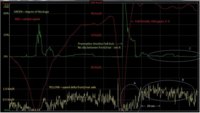

Not so good news is that the above seems to be true only on DSG gears 1-4 on vans equipped with 110kW/150PS engine. Test vans (1) and (2).

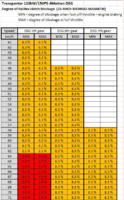

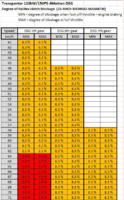

In the table below detailed values for “Degree of blockage” on these vans.

How to read.

Pick a line. For example line 80 km/h. R

On the 5th gear

- at full throttle degree of blockage is 7.5% - which is almost as expected.

- no throttle = engine braking, degree of blockage is 0% - rear wheels are freely rolling which is as expected – ok.

On the 6th gear

- at full throttle degree of blockage is 0% - which means the clutch is disengaged – no torque to rear axle, van is front wheel driven.

- no throttle = engine braking, degree of blockage is 0% - rear wheels are freely rolling which is as expected.

On the 7th gear

- at full throttle degree of blockage is 8.3% - which means the clutch is engaged – actually at the maximum for that speed, maximum torque to rear axle.

- no throttle = engine braking, degree of blockage is still 8.3% - which is not as expected – the clutch is always engaged at the maximum coupling for that speed, maximum torque to/from rear axle.

A sample from a 110kW/150PS DSG van (1) graphed: Symbology as in the first graph. Gears used marked in the picture. Note and compare speed delta (yellow at the bottom) with the first picture.

Manual gearbox

No, I can't tell whether the same is true with manual gearbox. I haven't had a chance to hook up to one, yet. I am definitely interested to hear if things are any different....

To be continued...

Last edited:

especially on lower gears

especially on lower gears