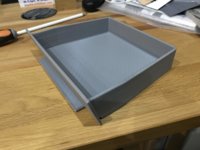

Right then, nailed it, after two prototypes. Here's my 3d printed cubby hole tray.

MK1 jammed half way in so i had to taper the sides and the tray top part.

MK2 fit well but the front face of the tray was at a slightly different angle to the hole and looked bad.

MK3 is cock on. It slides in well, the tapered groove on the bottom of the tray fits really well over the lip of the cubby hole and pulls the front in (due to the taper) and the front face is parallel with the face of the hole. It doesn't slide rattle or squeak in the slightest either which is also paramount for my sanity.

It's been a really good project to get me up to speed with the CAD system, the slicer software and the 3d printer. Today's first print of MK3 was printed on a coarse setting, almost twice as fast and still has a pretty good finish.

It's now filled with coffee vouchers from McD's a few business cards and other assorted bits and pieces. Job done.

MK1 jammed half way in so i had to taper the sides and the tray top part.

MK2 fit well but the front face of the tray was at a slightly different angle to the hole and looked bad.

MK3 is cock on. It slides in well, the tapered groove on the bottom of the tray fits really well over the lip of the cubby hole and pulls the front in (due to the taper) and the front face is parallel with the face of the hole. It doesn't slide rattle or squeak in the slightest either which is also paramount for my sanity.

It's been a really good project to get me up to speed with the CAD system, the slicer software and the 3d printer. Today's first print of MK3 was printed on a coarse setting, almost twice as fast and still has a pretty good finish.

It's now filled with coffee vouchers from McD's a few business cards and other assorted bits and pieces. Job done.