Hi all,

Desperately looking for some assistance!

I have a 2018 204 DSG high line. Had it from 8k miles, now has 82k on the clock. I’ve done all of the servicing and maintenance on it as I’m very mechanically minded and my business is automotive electrical design.

However, I have a fault that I cannot get to the bottom of.

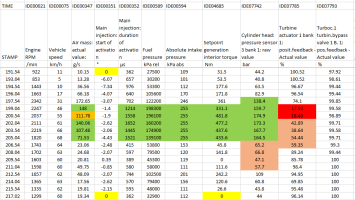

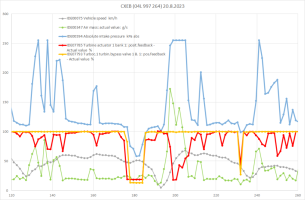

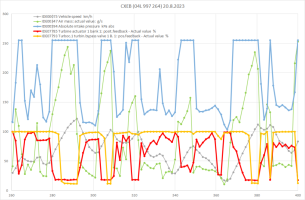

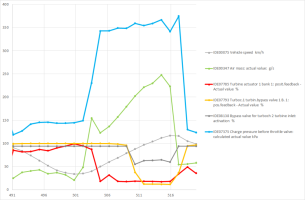

I have VCDS so can take data logs etc.

It’s showing no fault codes.

You can be driving along normally and then suddenly the engine will completely cut power for a quarter of second and then continue fine. I can do a 100 mile trip without it happening, but then it could do it 10 times on a 5 mile trip.

It’s had 1 fault code for a while for EGR insufficient flow but last night I finally got around to changing the EGR valve and cooler and hoped that would solve the cutting issue, but it hasn’t.

I’ve also just given it a full service plus DSG oil and filter, glow plugs and fuel filter.

If anyone can help, it would be most appreciated!! We are going away in it at the end of the month so I really need to get it sorted!

Desperately looking for some assistance!

I have a 2018 204 DSG high line. Had it from 8k miles, now has 82k on the clock. I’ve done all of the servicing and maintenance on it as I’m very mechanically minded and my business is automotive electrical design.

However, I have a fault that I cannot get to the bottom of.

I have VCDS so can take data logs etc.

It’s showing no fault codes.

You can be driving along normally and then suddenly the engine will completely cut power for a quarter of second and then continue fine. I can do a 100 mile trip without it happening, but then it could do it 10 times on a 5 mile trip.

It’s had 1 fault code for a while for EGR insufficient flow but last night I finally got around to changing the EGR valve and cooler and hoped that would solve the cutting issue, but it hasn’t.

I’ve also just given it a full service plus DSG oil and filter, glow plugs and fuel filter.

If anyone can help, it would be most appreciated!! We are going away in it at the end of the month so I really need to get it sorted!