You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sound-deadening & Carpet-lining wheel arches.

- Thread starter David Robinson

- Start date

Thanks. I’ll check it out.It’s worth doing the steel arch but far more noise reduction is achieved by doing the all four wheel arch liners - have a search on ‘sound deadening‘ on the Forum.

Carpet on the arches. Sound deadening on the outside.

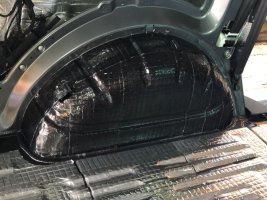

@Nosnittap - this is what @AJCConversions do to wheel arches:Do I put only sound deadening on wheel arches or do I thermal line them too.

irishnutjar

Member

As in the plastic liners? Had a quick look & cant find the thread you are talking about?It’s worth doing the steel arch but far more noise reduction is achieved by doing the all four wheel arch liners - have a search on ‘sound deadening‘ on the Forum.

As in the plastic liners? Had a quick look & cant find the thread you are talking about?

I added 10mm self adhesive acoustic foam to the front arch liners today, from the top down to the rear, the front half left bare. It made a noticeable difference for very little cost and time. There was no requirement to use longer screws as cut out for the body flange and two pads on the liner.

All arches are now externally fitted with Dynamat Xtreme, rear liners completely covered with 10mm foam and front liners covered 50%.

Both doors are done with Dynamat Xtreme and 10mm foam on the cards.

Both front wings are done with Dynamat, they ring like a cymbal when bare, not sure how much was entering the cab so did them anyway.

Rest of the van was done professionally with Silent Coat and foam except the cab floor which I’ll be leaving for now.

Next I’m doing the front steps and scuttle.

I highly recommend foam coating the arch liners.

irishnutjar

Member

Do you mean the plastic liners? Thats interesting- any pix please?

No I don’t, have a read through this discussion. It’s very straight forward.Do you mean the plastic liners? Thats interesting- any pix please?

Wheel-arch - Sound-Deadening internally or externally?

While fitting wheel spacers (25mm) this weekend, I took the opportunity to also remove the wheel arch liners and stick Silent Coat to the wheel arches for improved sound proofing. After doing so, I then became concerned that I have perhaps introduced a moisture trap to the underside of my van...

Heat gun to soften then butyl sheets & PTFE/nylon “Dobber” to work them into the contours - rollers can work fine if you have them, but as the look is of secondary importance , I didn’t worry about marking the foil surface & just used a plastic paintbrush handle.

Don’t forget butyl deadening effects the model response of the panel (so we don’t hear the treble when stuck) - its great but doesn’t prevent thermal heat transfer, albeit the aluminium foil will help reduce thermal radiation loss, but not conductive losses. You’ll need closed cell foams as your next layer Ideally.

Final thing - gloves & gauntlet if you have them. That foil is razor sharp………and you’ll slice yourself pushing sheets behind structure if you don’t wear long sleeves,

Don’t forget butyl deadening effects the model response of the panel (so we don’t hear the treble when stuck) - its great but doesn’t prevent thermal heat transfer, albeit the aluminium foil will help reduce thermal radiation loss, but not conductive losses. You’ll need closed cell foams as your next layer Ideally.

Final thing - gloves & gauntlet if you have them. That foil is razor sharp………and you’ll slice yourself pushing sheets behind structure if you don’t wear long sleeves,

Wheel-arch - Sound-Deadening internally or externally?

While fitting wheel spacers (25mm) this weekend, I took the opportunity to also remove the wheel arch liners and stick Silent Coat to the wheel arches for improved sound proofing. After doing so, I then became concerned that I have perhaps introduced a moisture trap to the underside of my van...

Perfect, thanksWe do the higher parts of the arch. This also gives a better effect when carpet linned as the height of the lower parts and the higher parts is greater difference.

We don't do bottom edge as this effects floor fitting.

I'm sure the pictures will explain better than me

View attachment 211724

View attachment 211725

You can add to the top inner wheel arch, but don't see much point on the inner top cill

Do you mean the sound deadening or the thermal liner or both?You can add to the top inner wheel arch, but don't see much point on the inner top cill

Similar threads

- Replies

- 1

- Views

- 469

- Replies

- 6

- Views

- 1K

- Replies

- 1

- Views

- 825

- Replies

- 5

- Views

- 1K