Ok, thanks; I've just paid for the VIP membership.

"Most folks replace the relay completely" - I'm guessing you meant bypass the relay?

Yes, bypass or even remove it completely. Many remove or relocate the fuse/relay brackets and tuck the connectors under carpet. Space is premium especially under single seat and it will be tight to fit a battery and all leisure electrics into the seat base. So, every little bit of removed unnecessary stuff helps.

I would have thought a quality DC-DC charger would know if the engine was running or not anyway, but I'll have to look into this.

Yes and no. Chargers can indeed sense the main battery voltage and turn themselves on based on that. The trouble is that T6 has a smart alternator and battery management system for the main battery - depending on battery SOC the alternator can be completely off even when engine is running. It’s perfectly normal to see anything between 11.9 and 14.9V on main battery with engine running - it makes it hard for dc-dc chargers to be very smart about their charging decisions.

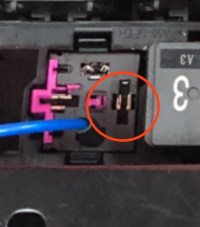

. Can't really see the maxi fuse ampage in your pic, is it 80A or something less? If it's 80A it's probably just in different slot compared to mine.

. Can't really see the maxi fuse ampage in your pic, is it 80A or something less? If it's 80A it's probably just in different slot compared to mine.