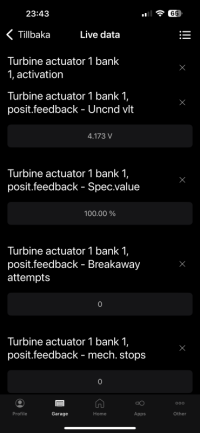

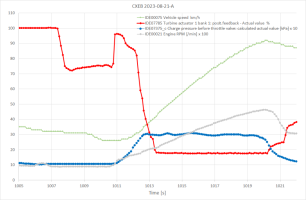

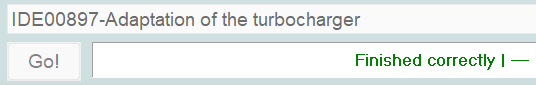

Wow, thanks!Meanwhile - it seems that we can run the G581 into different position via engine's Basic Settings > IDE00457 - Test of turbocharger. Test runs for 60 seconds sweeping the actuator a couple of times.

View attachment 262393

View attachment 262392

However, I'm not sure if OBDeleven can make a log while test is running. At least in the past it didn't have the capability.

[T6_measured] 01-Engine - Built-in tests for turbocharger

01-Engine - Basic Settings IDE00457-Test of turbocharger HOW-TO Engine running VCDS > Select > Engine > Basic Settings > IDE00457-Test of turbocharger Select "Measuring Values" Pick up e.g. the following data items for monitoring: IDE00021 Engine RPM IDE07736 Turbocharg.2 compress.outlet...www.t6forum.com

This is giving me alot of more hope! I spoke to my tuner that would let me use his VCDS if I wanted to. The thing is I have to drive the van 35km to do so. If the new N75 makes no difference I know exactly know what rabbithole to go down.