Passive regen & particle matter sensor

- Thread starter Dm85

- Start date

Please clarify - do you mean soot level doesn't decrease, or something else?trying to figure out why passive regen doesn’t get recorded by the ecu

To make soot level actually decrease within passive regeneration just need to get hot enough exhaust gases into DPF to get soot burned off.

E.g. below some soot burn-off while driving was observed

NOx sensor and Adblue faults codes

Hi @mmi Well, thank you for the steep, but guided learning curve! I haven’t yet though managed to find the ‘Live’ readings including speed at fault as on your fault log printout. Luckily my joyride included around a town bypass, to the roundabout at the end and back the same route. So, I...

should the particle matter sensor exhaust temperature be higher than what the sensor is reading after a trip down the motorway?

Sounds normal to me - see belowAfter a few logs it never goes above 26 degrees……

[T6_measured] Monitoring DPF regeneration, DPF condition, EGR operation

Sweet, thank you! I will poke around and see if I could use this kind of approach in some plots! Just read your posts about PIDs, if you need a hand to process your csvs don't hesitate ! we can maybe come up with a standardized processing. I'll do it with with mine from mmi's torque config and...

and then about the particulate matter sensor itself and about it's regeneration

[T6_measured] Monitoring DPF regeneration, DPF condition, EGR operation

Sweet, thank you! I will poke around and see if I could use this kind of approach in some plots! Just read your posts about PIDs, if you need a hand to process your csvs don't hesitate ! we can maybe come up with a standardized processing. I'll do it with with mine from mmi's torque config and...

i started to check different temp sensors and noticed this seemed quite low but not sure how it reads.

I have found that soot builds up regardless of a long journey (so not calculating passive?) and it’ll do an active regen with in between 100 to 130 miles depending on driving habits. I also get a P20EE that shows up after a longer run only. I have monitored NOX and ad blue injection rates and there’s fairly high spikes in Nox and seeming low ad blue injection. I have done the vcds dosing test and the injector sprays ok and consistent. So I was looking for other reasons for this and noticed the temp is low for a motorway journey considering it states exhaust temps in that particular sensor

I have found that soot builds up regardless of a long journey (so not calculating passive?) and it’ll do an active regen with in between 100 to 130 miles depending on driving habits. I also get a P20EE that shows up after a longer run only. I have monitored NOX and ad blue injection rates and there’s fairly high spikes in Nox and seeming low ad blue injection. I have done the vcds dosing test and the injector sprays ok and consistent. So I was looking for other reasons for this and noticed the temp is low for a motorway journey considering it states exhaust temps in that particular sensor

Yes, it does unless you can keep exhaust temperature in the DPF at or above 600 °C. Then the soot burn rate would exceed soot accumulation rate. To make that happen the speed needs to be kept well above 80 mph.I have found that soot builds up regardless of a long journey

Possibly just a software issue - there was an update campaign to cure this issue.I also get a P20EE that shows up after a longer run only.

[T6_measured] NOx emissions, AdBlue consumption, DPF regeneration - Before and after ECU update

Introduction An update campaign for T6 EU6 diesel engines took place in 2019-20. Affected engines were on van of model years MY16-MY18, including some of MY19. For M1 class (passenger carriers, VIN WV2...) the update was an official recall. For N1 class (VIN WV1....) the update was not...

I think the temperature is not engine's exhaust temperature but sensor's own "exhaust" temperature as the particle sensor also "regenerates" itself regularly as part of particle detection measurement. Next to particle sensor there is a deidcated exhaust temperature sensor which should show more "normal" values.So I was looking for other reasons for this and noticed the temp is low for a motorway journey considering it states exhaust temps in that particular sensor

Also I'm not sure how to interpret the value as originally it's just 16 bits of data. The diagnostic tool interprets it as signed integer divided by 10 to show us what we see - maximum typically about 26 units. However, just checked quite a few logs of cold engines at various ambient temperatures and I'm inclined to believe the number diagnostic tool now shows should be actually multiplied by 10 (thus no scaling of the CANbus 16 bit data).

Code:

IDE00025 Coolant temperature 22 °C

IDE00196 Engine oil temperature 21.1 °C

IDE07987 Particle sensor: exhaust temperature 2.2 °C

Code:

IDE00025 Coolant temperature -27 °C

IDE00196 Engine oil temperature -27.6 °C

IDE07987 Particle sensor: exhaust temperature -3.2 °CJust to re-iterate - as I mostly do shorter drives during normal life, when we do drive up a motorway - it is usually in 4th gear at 3000-3200 rpm - for at least an hour at a time at least a couple times a month in the hope that it might help towards prolonging the life of the DPF etc.

(150psi/6gear)

Very rarely use that 6th gear as it is almost like driving in town - handy if you are motorwaying all the time though, I am sure.

(150psi/6gear)

Very rarely use that 6th gear as it is almost like driving in town - handy if you are motorwaying all the time though, I am sure.

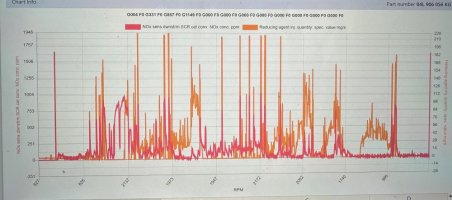

I can see from the other post it’s more the current draw that shows how it’s working? I will log that also. I wasn’t to aware of the temp reading characteristics, just thought it looked odd. I’ve attached a log graph of ad blue quality and nox levels. Should the able keep up with the nox levels and they seem a bit high to me?Yes, it does unless you can keep exhaust temperature in the DPF at or above 600 °C. Then the soot burn rate would exceed soot accumulation rate. To make that happen the speed needs to be kept well above 80 mph.

Possibly just a software issue - there was an update campaign to cure this issue.

[T6_measured] NOx emissions, AdBlue consumption, DPF regeneration - Before and after ECU update

Introduction An update campaign for T6 EU6 diesel engines took place in 2019-20. Affected engines were on van of model years MY16-MY18, including some of MY19. For M1 class (passenger carriers, VIN WV2...) the update was an official recall. For N1 class (VIN WV1....) the update was not...www.t6forum.com

I think the temperature is not engine's exhaust temperature but sensor's own "exhaust" temperature as the particle sensor also "regenerates" itself regularly as part of particle detection measurement. Next to particle sensor there is a deidcated exhaust temperature sensor which should show more "normal" values.

Also I'm not sure how to interpret the value as originally it's just 16 bits of data. The diagnostic tool interprets it as signed integer divided by 10 to show us what we see - maximum typically about 26 units. However, just checked quite a few logs of cold engines at various ambient temperatures and I'm inclined to believe the number diagnostic tool now shows should be actually multiplied by 10 (thus no scaling of the CANbus 16 bit data).

Code:IDE00025 Coolant temperature 22 °C IDE00196 Engine oil temperature 21.1 °C IDE07987 Particle sensor: exhaust temperature 2.2 °CCode:IDE00025 Coolant temperature -27 °C IDE00196 Engine oil temperature -27.6 °C IDE07987 Particle sensor: exhaust temperature -3.2 °C

That was a hot engine on motorway. The nox sensor only wakes up at a certain temperature so no reading when coldWas that graph taken from a cold or hot engine?

If cold, could you take a reading from a hot one (and v.v) - see if there is a marked difference.

Could you please post the actual data - it's a bit difficult to interpret from the picture what e.g. the average would be - as I think it's the long term average that counts, not individual peaks. Would be useful to include in data logs also vehicle speed, air mass flow and exhaust temperature into DPF to evaluate engine load.I’ve attached a log graph of ad blue quality and nox levels. Should the able keep up with the nox levels and they seem a bit high to me?

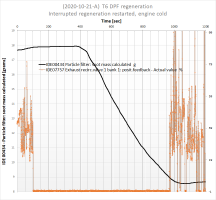

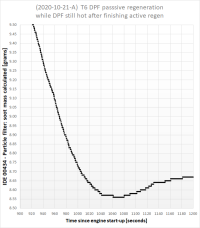

The most noticeable moment for passive regeneration is immediately after DPF regeneration has finished (either at 9.00 or 6.00 grams of soot calculated) as the DPF is still hot enough for a few minutes - the soot level still decreases some time and eventually starts climbing again when DPF output temperature reaches about 500 C.it has never passively decreased the soot in the DPF

Below the EGR valve's nonzero positions (orange) shows the exact moments of DPF regeneration's start and finish. Here about 90 seconds of passive regeneration (from 970 to 1060 seconds, soot down from 9.00 to 8.56 grams).

More fancy graphs in

[T6_measured] DPF regeneration vs. short journeys

Got curious how T6 copes with doing short journeys. And how short would be too short for successful DPF (Diesel Particulate Filter) regeneration. The graphs below are result of doing short journeys - the plotted one is number 3, thus two interrupted DPF regens before this. At this stage the...

I'm highly confident that by using 6th gear at the same engine revs the passive regeneration would lower the soot valueit is usually in 4th gear at 3000-3200 rpm -

I’ll send the vcds log over! I was logging today the PM sensor calculated current and it stayed at 0 through out the journey. Not sure if that is normal?Could you please post the actual data - it's a bit difficult to interpret from the picture what e.g. the average would be - as I think it's the long term average that counts, not individual peaks. Would be useful to include in data logs also vehicle speed, air mass flow and exhaust temperature into DPF to evaluate engine load.

Last edited:

That's a good thingthe PM sensor calculated current and it stayed at 0 through out the journey.

= no soot passed through the PDF.

= no soot passed through the PDF.A different case - soot registered - below:

[T6_measured] Monitoring DPF regeneration, DPF condition, EGR operation

@ebiii Attached an addendum to Torque - containing the following T6 PIDs "T6-01 Lambda" "T6-01 NOx sensor" "T6-01 Particle sensor current" "T6-01 Particle sensor operation time" NOTE: "T6-01 Particle sensor operation time" will be logged only once in 10 seconds - to not unnecessarily slow down...

Ah! Thats what that meansThat's a good thing= no soot passed through the PDF.

A different case - soot registered - below:

[T6_measured] Monitoring DPF regeneration, DPF condition, EGR operation

@ebiii Attached an addendum to Torque - containing the following T6 PIDs "T6-01 Lambda" "T6-01 NOx sensor" "T6-01 Particle sensor current" "T6-01 Particle sensor operation time" NOTE: "T6-01 Particle sensor operation time" will be logged only once in 10 seconds - to not unnecessarily slow down...www.t6forum.com

Similar threads

- Replies

- 40

- Views

- 4K

- Replies

- 2

- Views

- 2K

- Replies

- 13

- Views

- 1K

- Replies

- 3

- Views

- 747