I don't think you'll see anything, as the injection duration is at zero. When you said earlier it starts and runs on Easy Start, do you mean you have to keep feeding on Easy Start to keep it running, or once it's started on Easy Start, it will then run as normal ?Thank you very much Catfood12

I will certainly do that tomorrow and let you guys know how we get on

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Won’t start. No fault codes

- Thread starter aarona

- Start date

-

- Tags

- stop/start

Yes we have to keep feeding on easy start to keep it running once we stop feeding the easy start the van stopsI don't think you'll see anything, as the injection duration is at zero. When you said earlier it starts and runs on Easy Start, do you mean you have to keep feeding on Easy Start to keep it running, or once it's started on Easy Start, it will then run as normal ?

Not another one of these is it;

Diagnose Dan where a VAG TDI engine would only start from cold after a very long crank. Turned out to be the variable valve timing actuator losing oil and retarding the cam to a point where it wouldn't start. I was surprised at the time that it wouldn't at least splutter and fire. Afterwards I wondered if that was a safety feature that the thing wouldn't start at cranking revs with a so far retarded cam. There was no error codes on that either, and Dan found it (we diagnosed it together! ) by the number of pulses from the crank reluctor between TDC and the cam at first crank, and when it finally started. That could explain the queer phase angle here ...

) by the number of pulses from the crank reluctor between TDC and the cam at first crank, and when it finally started. That could explain the queer phase angle here ...

Diagnose Dan where a VAG TDI engine would only start from cold after a very long crank. Turned out to be the variable valve timing actuator losing oil and retarding the cam to a point where it wouldn't start. I was surprised at the time that it wouldn't at least splutter and fire. Afterwards I wondered if that was a safety feature that the thing wouldn't start at cranking revs with a so far retarded cam. There was no error codes on that either, and Dan found it (we diagnosed it together!

Sorry @mmi Only seeing this now, yes it's been cranked quite a few times since the timing belt was adjusted. I'll get it all put back together tomorrow and do another bookmap and another log and will post up. Thank you very muchWondering if the engine hasn't yet updated the value and thus refuses to fire the injectors.

IDE00182 Camshaft adaptation intake bank 1: phase position

Certainly worth doing!

Has it been seriously cranked after the latest timing belt adjustment?

Perhaps a few tries to crank (possibly logging too)?

Then finally another full blockmap capture so we can see if anything in the data has started to change?

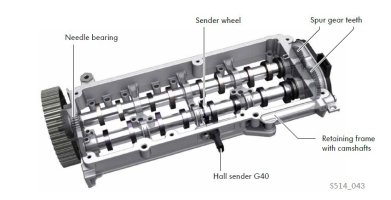

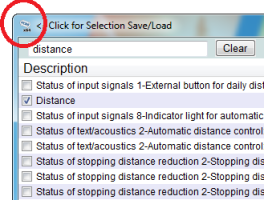

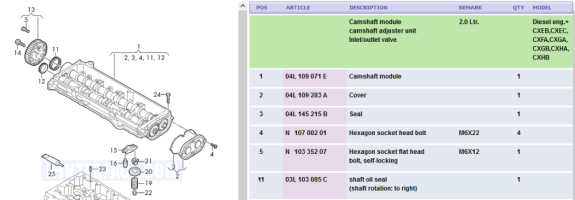

Ok, all we're left with is that the inlet cam is misaligned. The timing belt drives the exhaust camshaft, which we know is timed up OK. The camshaft position sensor however picks up only on the inlet camshaft, which is drive by spur gears at the back of the head via the exhaust camshaft. See diagram below.

I reckon they've installed the inlet camshaft incorrectly and it's timed up wrong, hence the incorrect phase angle being reported, so ECU won't fire the the injectors, as the thing is so far off the end stops of the map, similar to the other belt related non-starts. It's far enough out to stop the ECU working out when to send the fuel, but perhaps only a tooth or two, so close enough that the motor will run on Easy Start.

I reckon they've installed the inlet camshaft incorrectly and it's timed up wrong, hence the incorrect phase angle being reported, so ECU won't fire the the injectors, as the thing is so far off the end stops of the map, similar to the other belt related non-starts. It's far enough out to stop the ECU working out when to send the fuel, but perhaps only a tooth or two, so close enough that the motor will run on Easy Start.

Hi DXX we are in no way mechanic's this is the way we received the van from a so called specialist and we were told there was a new timing belt kit fittedThe photos of the timing belt you posted when showing the timing locking pins don’t look like a new timing belt, looks to be slightly worn.

Are you sure it is the correct timing belt?

Thanks again the van is booked in with another mechanic on Tuesday, I'll be sure to pass on all the info yous guys have provided to him. Really appreciate all the helpOk, all we're left with is that the inlet cam is misaligned. The timing belt drives the exhaust camshaft, which we know is timed up OK. The camshaft position sensor however picks up only on the inlet camshaft, which is drive by spur gears at the back of the head via the exhaust camshaft. See diagram below.

View attachment 139945

I reckon they've installed the inlet camshaft incorrectly and it's timed up wrong, hence the incorrect phase angle being reported, so ECU won't fire the the injectors, as the thing is so far off the end stops of the map, similar to the other belt related non-starts. It's far enough out to stop the ECU working out when to send the fuel, but perhaps only a tooth or two, so close enough that the motor will run on Easy Start.

It’s not unheard of for a mechanic to replace an item matching it to what is fitted rather than checking the correct part number.Looking at the cam you should try and get the pin in the centre of the elongated hole. Are you sure the crank is lining up as it should? Everything needs to be lining up. Worth spending time getting it right.

Just wondering if the first timing belt renewal which resulted in a failed tensioner was a result of an incorrect belt.

The subsequent replacement could have been made by simply matching to the original belt rather than checking the correct part is fitted.

Just a stab in the dark.

Sorry @mmi Only seeing this now, yes it's been cranked quite a few times since the timing belt was adjusted. I'll get it all put back together tomorrow and do another bookmap and another log and will post up. Thank you very much

Thanks. I would expect that if we do not see injectors to start firing in 2-3 seconds any further cranking won't do it either.

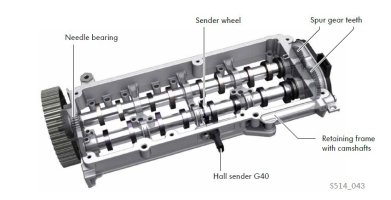

Here is a slightly modified proposal for the next logging during the cranking. Now the prime suspect "IDE00182 Camshaft adaptation intake bank 1: phase position" is also included on this "short list.

Either tick the following manually or preferably use attached preformatted file as explained further down.

The file must have extension .U01 thus remove the extras from the file name.

| IDE00021 | Engine RPM |

| IDE00182 | Camshaft adaptation intake bank 1: phase position |

| IDE00347 | Air mass: actual value: |

| IDE00351 | Main injection: start of activation |

| IDE00352 | Main injection: duration of activation |

| IDE00407 | Rail pressure regulation: status |

| IDE00416 | Starter control: terminal 50 feedback |

| IDE00589 | Fuel pressure |

| IDE07822 | Fuel pressure regulator valve: activation |

| IDE07824 | Tank-internal presupply pump 1 bank 1: activation |

| ENG113754-ENG113670 | P_L_Aps_synchronised_origin-Sync_origin |

| ENG113757 | P_L_Aps_timeout_detected |

Once you have ticked the parameters you could save (load) the measurement setup (e.g. the above) for the next run.

The search box helps to narrow down the parameters.

After loading the preset file you still need to

Tick "Group UDS requests" - by 7

Click Log - Start

Crank the engine - 3 seconds is enough.

Stop logging etc.

The logfile will be in folder C:\Ross-Tech\VCDS\Logs

Please post the logfile.

Attachments

I think the clip is not exactly applicable to T6 diesel - ours is a more primitive one inNot another one of these is it;

Diagnose Dan where a VAG TDI engine would only start from cold after a very long crank. Turned out to be the variable valve timing actuator losing oil and retarding the cam to a point where it wouldn't start. I was surprised at the time that it wouldn't at least splutter and fire. Afterwards I wondered if that was a safety feature that the thing wouldn't start at cranking revs with a so far retarded cam. There was no error codes on that either, and Dan found it (we diagnosed it together!) by the number of pulses from the crank reluctor between TDC and the cam at first crank, and when it finally started. That could explain the queer phase angle here ...

this area.

this area.Anyways, below a snippet from a Skoda engine on tick-over.

| IDE00178 | Camshaft adjustment intake bank 1: specified value | 10 | ° |

| IDE00179 | Camshaft adjustment intake bank 1: actual value | 10.06 | ° |

| IDE00182 | Camshaft adaptation intake bank 1: phase position | -0.81 | ° |

The respective camshaft adjustment values on T6 diesel engines stay at 0.0 degrees always.

Ahh this is brilliant Thanks again @mmi I'm away for a couple of days but will be sure to do this as soon as I'm back and I'll post ot straight up.Thanks. I would expect that if we do not see injectors to start firing in 2-3 seconds any further cranking won't do it either.

Here is a slightly modified proposal for the next logging during the cranking. Now the prime suspect "IDE00182 Camshaft adaptation intake bank 1: phase position" is also included on this "short list.

Either tick the following manually or preferably use attached preformatted file as explained further down.

The file must have extension .U01 thus remove the extras from the file name.

IDE00021 Engine RPM IDE00182 Camshaft adaptation intake bank 1: phase position IDE00347 Air mass: actual value: IDE00351 Main injection: start of activation IDE00352 Main injection: duration of activation IDE00407 Rail pressure regulation: status IDE00416 Starter control: terminal 50 feedback IDE00589 Fuel pressure IDE07822 Fuel pressure regulator valve: activation IDE07824 Tank-internal presupply pump 1 bank 1: activation ENG113754-ENG113670 P_L_Aps_synchronised_origin-Sync_origin ENG113757 P_L_Aps_timeout_detected

Once you have ticked the parameters you could save (load) the measurement setup (e.g. the above) for the next run.

The search box helps to narrow down the parameters.

View attachment 139958

After loading the preset file you still need to

Tick "Group UDS requests" - by 7Click Log - StartCrank the engine - 3 seconds is enough.Stop logging etc.The logfile will be in folder C:\Ross-Tech\VCDS\LogsPlease post the logfile.

If I may ask you a question, I was speaking to an old school diesel mechanic the other day he was saying in some ford's the cam lobes are sweated on and generally when the timing goes in 1 of those the cam lobs can move.

Is the T6 the same in respect to the cam lobs being sweated on ?

Thanks again for your help

I assume the cam lobes are sweated on also in T6 - just based on how camshafts are manufactured nowadays.If I may ask you a question, I was speaking to an old school diesel mechanic the other day he was saying in some ford's the cam lobes are sweated on and generally when the timing goes in 1 of those the cam lobs can move.

Is the T6 the same in respect to the cam lobs being sweated on ?

J and E Engineering Camshaft lobe alignment

J and E Engineering Services, Engine rebuilder and machine shop for modern and calssic car, commercial & plant engine rebuilding and machining service. Daimler V8 engine specialist. Specialist modifications, parts and tools for Daimler V8 engines.

Camshaft Modules - SLPT

Camshaft modules are a high-value solution with reduced cost, mass and complexity to conventional cam in head capped designs

Cams and Camshafts

Anyways, I'm assuming it shouldn't be a the problem for the phase offset we are working on - because there is no mecahnical stress on sender wheel for Hall sensor which registeres intake camshaft position.

The full document available in T6Forum downloads

SSP 564 - The T6 2.0L TDi

VW Self Study Programme, Document 564 - The 2.0 litre TDI Engine In The T6 The introduction of modern, particularly efficient Euro-6 engines represents a central feature of the new T6. All units are equipped with Blue Motion Technology as...

However, the exhaust camshaft is the one driven by the toothed cambelt. The intake camshaft is driven via spur gearing by the exhaust camshaft. As @catfood12 in post #46 mentions there is a possibility for a mistake in camshaft installation. However, for engine CXGB the OEM spare is a full preassembled module (below) which probably can't be disassembled.

Source: IFInterface

Yes please - the setup records more parameters about crankshaft-camshaft sync process - I'm especially curious to see if there will be any "wobble" in phase offset during cranking.Ahh this is brilliant Thanks again @mmi I'm away for a couple of days but will be sure to do this as soon as I'm back and I'll post ot straight up.

Please do a data logging with the new setup file and post the data.Ahh this is brilliant Thanks again @mmi I'm away for a couple of days but will be sure to do this as soon as I'm back and I'll post ot straight up.

Before (possibly) taking cambelt off perhaps you could try do the same recording when camshaft sensor (G40) is disconnected (inspired by this thread here)

Tranporter -16 won´t start with camshaft sensor connected, starts but throws multiple DTC´s when its disconnected

Having trouble to start a Transporter -16 with 2.0cr CXHA 150ps diesel Timing belt snapped and new cylinder head is fitted. Car refuses to start when cranking crank rpm showing~320-330rpm Camshaft rpm showing ~300-310 (shouldn´t these be exactly the same?) Getting fault code: 27320 P03A0...

I'd like to propose the following:

VCDS Preparations

- Ignition ON

- Do full VCDS-Auto-Scan: VCDS > Auto-Scan > Start (on T6 VCDS detects all modules automatically, no need to select chassis) > Save

- Read engine faults codes: VCDS > Select > Engine > Fault Codes > Save Codes > Clear Codes > Save Codes

- Ignition OFF

Disconnect the camshaft position sensor (G40) connector

It's located between injectors 2 and 3. According to repair manual should be enough just to loosen charge air cooler on top of camshaft module. Anyways, shouldn't take too long even if some more disassembly is required - the picture below was taken after 20 minutes of tear-down - although not by me

Please find T6 CXGB engine repair manual >here<

For disconnecting the sensor G40 - pages 384, then 389, etc.

For disconnecting the sensor G40 - pages 384, then 389, etc.

VCDS Data logging

- Ignition ON

- Read engine faults codes: VCDS > Select > Engine > Fault Codes > Save Codes > Clear Codes > Save Codes

- Start data logging (Adv. Meas.Values etc.) with the setup file - please do not forget to tick the "Group UDS Requests by 7" (greatly enhances sampling rate)

- Crank the engine - preferably at least 5 seconds.

- Stop the logging

- Read engine faults codes: VCDS > Select > Engine > Fault Codes > Save Codes

- Do full VCDS-Auto-Scan: VCDS > Auto-Scan > etc.

Good luck! I do really appreciate your efforts and sharing the logged data!

Did you do any of the proposed VCDS data logging (above)?Nice, if i disconnect camshaft sensor, engine will start so i quess camshaft module needs to be replaced.

Similar threads

- Replies

- 39

- Views

- 2K

- Replies

- 49

- Views

- 5K

- Replies

- 11

- Views

- 400

- Replies

- 1

- Views

- 824