is there a how to on here for what you will need from me.

Please post the following:

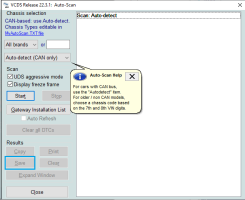

1) VCDS Auto-Scan

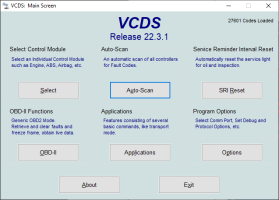

Plug in VCDS dongle.

Start VCDS on computer.

IGNition ON

On VCDS click Auto-Scan

(Below)

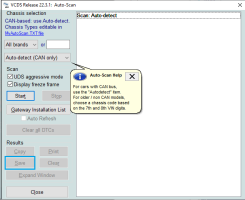

Click Start - let VCDS use Auto-detect and settings as below ... it takes a few minutes to scan all the modules

When finished, under Results click Save - to create a file Log-WV1ZZZ7Hxxxx.txt file in folder C:\Ross-Tech\VCDS\Logs\

Also Copy can be used to copy and paste e.g. here, or into Notepad

Post/attach the Auto-Scan file.

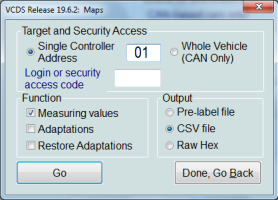

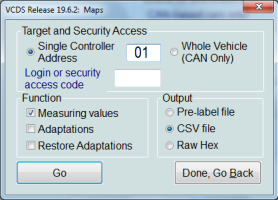

2) VCDS engine blockmap data

IGNition on (engine not running)

VCDS > Applications > Controller Channel Map >

Tick/fill boxes as above and click Go.

VCDS flashes screens for about 70 seconds (when finished hit "Done, Go Back") and there will be file blockmap-01-...csv in folder C:\Ross-Tech\VCDS\Logs\....

Please post/attach the blockmap file.

3) VCDS log when cranking the engine

Ignition ON

VCDS > Select > Engine > Adv. Meas. Values >

Tick the following items

IDE00021 Engine RPM [1/min]

IDE00347 Air mass: actual value: [g/s]

IDE00352 Main injection: duration of activation [µs]

IDE00406 Camshaft RPM [1/min]

IDE00407 Rail pressure regulation: status

IDE00589 Fuel pressure [kPa]

IDE05632 Fuel pressure regulator valve actual value [mA]

IDE07744 Particle filter: air pressure sensor 1 bank 1: raw value [mbar]

IDE07757 Exhaust recirc.valve 1 bank 1: posit.feedback - Actual value [%]

IDE07822 Fuel pressure regulator valve: activation [%]

IDE07819 Fuel high pressure sensor: unconditioned voltage [V]

IDE07824 Tank-internal presupply pump 1 bank 1: activation [%]

IMPORTANT:

Tick Group UDS requests by 7 (or 8, whichever value keeps data alive)

Click Log - Start !!!

Crank the engine - 5 seconds is enough

Stop logging etc.

The logfile LOG-01-IDE00021.....csv will be in folder C:\Ross-Tech\VCDS\Logs

Please post/attach the logfile.