Thank you very much for the log files - and especially having markers in the files - helps to pinpoint and confirm the moments of the issues.

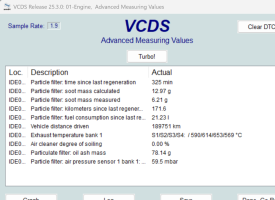

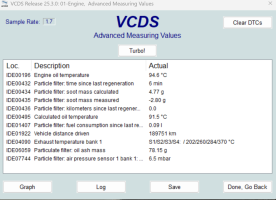

Some preliminary thoughts... about the last logged session (of total of three in the recording).

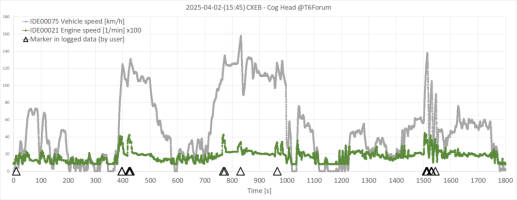

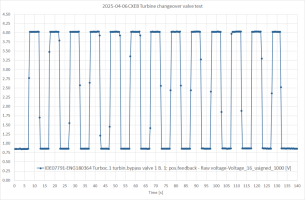

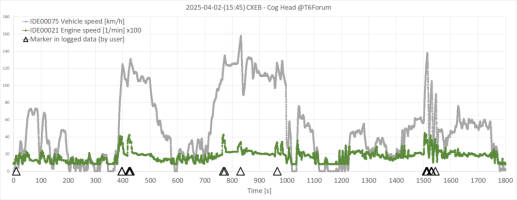

Large scale view in time of markers whereabouts

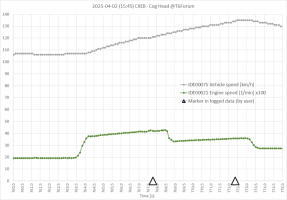

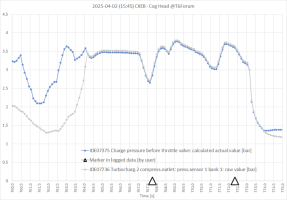

A downselected period for closer view - from 760 to 775 seconds

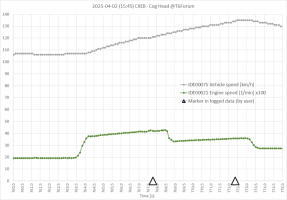

Well, probably the most illuminating period because of

- high vehicle speed = high engine load

- only few gear changes

- also "things" happen at slower rate thus easier to understand

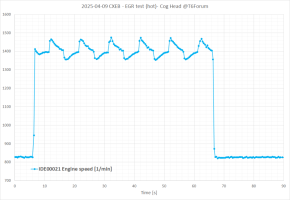

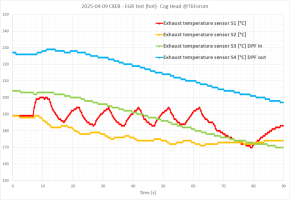

General conditions - speed, engine revs

No noticeable glitches in engine speed signal - not even by zooming in.

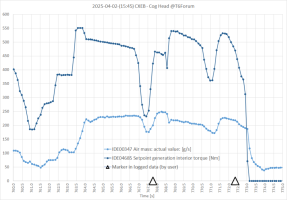

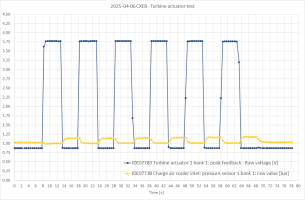

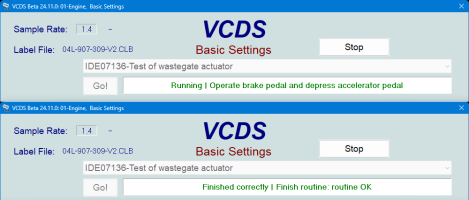

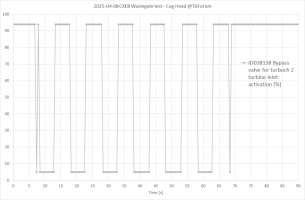

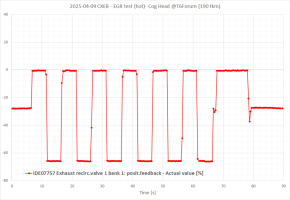

Turbo actuators

Obviously at about 764 seconds the pedal was floored, the gear was stepped down to 4th at 764 seconds, and stepped up into 5th at 768.5 seconds.

Turbo vane actuator (blue) and turbine changeover actuator (grey) reach and stay at their "full blast" positions.

Turbo wastegate (red) regulates charge pressure until...

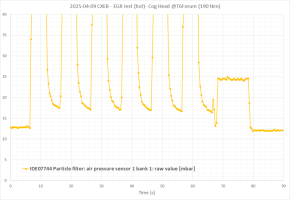

Charge pressures as seen by the ECU

I guess the pressure drop seen at 767 and 770.5 seconds drive the ECU to start to close the wastegate (squared red in picture one above).

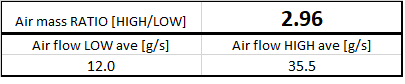

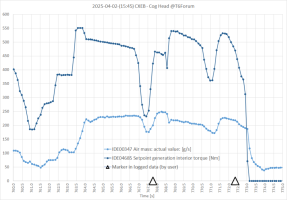

Air mass flow & engine torque

Air mass flow is in sync with charge pressure - quite naturally. And of course the recorded/calculated engine torque follows.

QUESTION - does this happen also on gear 7?

In the log the 6th gear was used and marked at 830 seconds (below).

It has been remapped, though I don't think it was a very good one.

My guess is that the turbo just can't handle the excessive air flow and the airflow in turbine vanes simply suddenly "slips"

???

Unfortunately I don't have reference values at the same conditions (4th gear full blast at and above 3800 RPM). Only thing similar by speed I found was only 130 grams/second of air flow - just barely half - but that's on 7th gear so also number of cylinder fill-ups is about half of what would have been on 4th gear.

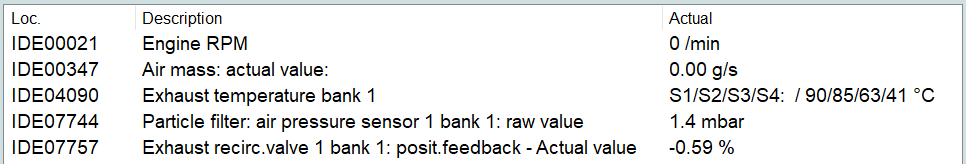

Of course a culprit could also be a misbehaving manifold pressure sensor (which are known to get clogged). Or misbehaving wastegate actuator or valve.