A little update on my post above. The black plastic arm I bought from ebay, snapped, before i refitted the motor! It snapped during the setting stops procedure using VCDS, the motor kept trying to puch past the end stops. So I contacted Tony P and ordered a couple of his white plastic arms (much better quality). After the ebay black arm snapped, I started thinking that maybe it was the HAVC control unit was faulty and was sending bad instructions, so I disconnected it to examine it and ordered another cheap one from ebay for testing.

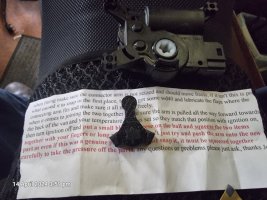

Meanwhile, I also kept researching, I started reading about the stepper motor potentiometer getting gunked up with grease and giving bad readings. I bought this van 3rd hand, the previous owner had it in a garage last December getting the heater fixed, the motor had been replaced then, but what if the garage had bought a 2nd hand motor from ebay? So, I opened up the motor and I found a big pool of grease in the corner. I cleaned out all of the grease using a spray contact cleaner and tested it with a multimeter.

In the meantime, Tony P's replacement plastic arms turned up, I had x2 to play with, so I hooked up the orignal HAVC control unit and fitted one of Tony P's and ran the VCDS calibration for the end stops, this time it actually worked, the motor stopped trying to drive past the end stops.

Now, I'm not sure whether cleaning the potentiometer in the motor fixed it, or disconnecting the HAVC control unit and reconnected it did, or it was a combination of the two!

NB; I managed to dig out the original snapped plastic arm which had fell down into the abyss below the gear stick, it turned out to be one of Tony P's 3d printed arms, so the garage that tried to fix the heater last December must have been on this thread and ordered one from Tony P.

So if anyone is struggling with this fault, this is what to do.

1. Order replacement arm from

@Tony P.

2. Open up motor and clean the potentiometer (black circle thing on green PCB)

3. Disconnect the HAVC unit for 24 hrs and reconnect.

4. Test and calibrate motor end stops with new arm using VCDS before refitting to heater unit and linkage.

5. Refit once happy.

Fingers crossed this will hold out.