You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

LED headlights got the pro's puzzled

- Thread starter Dav-Tec

- Start date

-

- Tags

- led headlights

Just a thought but is it certain that this only happens with dipped beams and not on other circuits fed by BCM such as high beams etc?

Since exact same fault on two distinct circuits at the same time sounds unlikely, maybe it could be power / ground issue in the microcontroller or "relay control" side of the BCM rather than the actual power feeds to the dipped beams. Dipped beams just might be the most obvious ones to see the issue in the first place.

Since exact same fault on two distinct circuits at the same time sounds unlikely, maybe it could be power / ground issue in the microcontroller or "relay control" side of the BCM rather than the actual power feeds to the dipped beams. Dipped beams just might be the most obvious ones to see the issue in the first place.

Hi mate this was my first thought but both light's and BCM have been swapped out as part of the fault finding with no changeJust a thought but is it certain that this only happens with dipped beams and not on other circuits fed by BCM such as high beams etc?

Since exact same fault on two distinct circuits at the same time sounds unlikely, maybe it could be power / ground issue in the microcontroller or "relay control" side of the BCM rather than the actual power feeds to the dipped beams. Dipped beams just might be the most obvious ones to see the issue in the first place.

Yes, I saw the BCM and light's were changed but I actually meant the power and ground wires that make the BCM tick in the first place - 'scuse my FinglishHi mate this was my first thought but both light's and BCM have been swapped out as part of the fault finding with no change

Sort of the power feed you would use in bench testing the BCM to get it respond to canbus, like pictured in Bench Test ECU/ECM Turn on Ignition?. Unfortunately I don't know the actual pins but just thought that if the powering to the microcontroller side of the BCM was glitching it might cause all kinds of issues - but they would probably not be limited just to dipped beams.

Anyway, good luck finding the issue!

So looks like it must be on van's side - not the headlight itself.I connect the scope at the plug of the drivers and passengers headlight with the lights still plugged in so everything is under load. Pin 6, yellow wire that supplied the dipped beam on the drivers headlight

Have you used VCDS to monitor in parallel what the BCM itself thinks - measurement block/group 042 would capture both left/right and low/high beam statuses.

By selecting only block 042 for logging would give approx. 7 Hz sampling rate - thus glitches more than 0.2 seconds should be captured.

No not tried that yet to be honest buddy but I've put it on the list. Currently neck deep in wiring.So looks like it must be on van's side - not the headlight itself.

Have you used VCDS to monitor in parallel what the BCM itself thinks - measurement block/group 042 would capture both left/right and low/high beam statuses.

By selecting only block 042 for logging would give approx. 7 Hz sampling rate - thus glitches less than 0.2 seconds should be captured.

UPDATE: It took a while but it's bloody FIXED!

Checked the battery as suggested ( I bought a new Snap-On toy...Erm I mean battery tester) and extensive investigation of the wiring loom in the engine bay/scuttle panel areas. Earth points stripped, cleaned and a couple added in as I wasn't convinced on one of the earths. It seemed to give some strange readings. I bought another toy... I mean tool a Picoscope 2204a Oscilloscope, the handheld is great for guidance but for the in depth nitty gritty this thing is ACE!

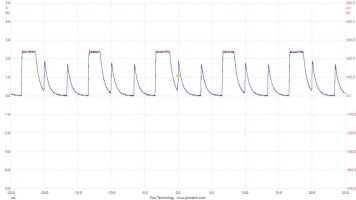

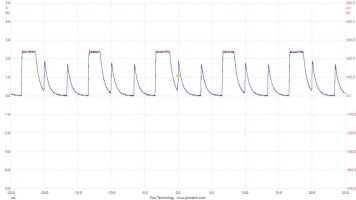

Picoscope connected up and found the PWM (Pulse Width Modulation) wires on both lights would fault when the lights blinked (couldn't captured this on the handheld as no record function). Admittedly it was a consistent signal when the light faulted but not how it should of looked. So connected one channel to PWM and then decided to track what the voltage to the dipped beam did during fault, to see if it was isolated to the PWM. It wasn't (pictures attached showing the fault when the light was off for around 6 seconds. Usually it would be a split second, but every so often it would be for quite some time).

Faulting

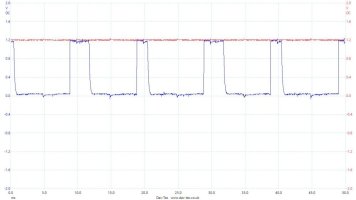

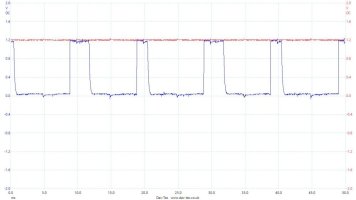

Fixed

So comfort and the rest of the lower dash stripped out and the wiring loom investigated. There was some questionable connections made and not by the customer, by a previous "pro" (red crimps on 0.35 and 0.5 wires and scotch locks comes on seriously). They where removed and replaced with solder, heat shrink (another new snap on toy! It's been an expensive week or 2) and the appropriate tape.

Eventually I found part of the main wiring harness leading towards the bulkhead had rubbed badly due to it not being secured where it once was. Access from the dash side was dire so wipers off and the big square blower blank/grommet removed for easier access. Found 5 wires had partial damage to the insulation these where repaired. 3 also turned out to be one of the PWM and dipped beam wires. These where repaired and the fault stopped. Van kept overnight for a day for monitoring purposes (this had me paranoid by this point) but the customer picked the vehicle up 26th May a d has said it hasn't faulted once!

I'd just like to say a MASSIVE thank you for everyone's input. It can be pretty lonely when you have a fault you can't get to the bottom of and know one else to consult with. Absolutely love this forum. There's probably some bits I've forgot to mention I'll update if anything springs to mind.

Cheers

Chris

Checked the battery as suggested ( I bought a new Snap-On toy...Erm I mean battery tester) and extensive investigation of the wiring loom in the engine bay/scuttle panel areas. Earth points stripped, cleaned and a couple added in as I wasn't convinced on one of the earths. It seemed to give some strange readings. I bought another toy... I mean tool a Picoscope 2204a Oscilloscope, the handheld is great for guidance but for the in depth nitty gritty this thing is ACE!

Picoscope connected up and found the PWM (Pulse Width Modulation) wires on both lights would fault when the lights blinked (couldn't captured this on the handheld as no record function). Admittedly it was a consistent signal when the light faulted but not how it should of looked. So connected one channel to PWM and then decided to track what the voltage to the dipped beam did during fault, to see if it was isolated to the PWM. It wasn't (pictures attached showing the fault when the light was off for around 6 seconds. Usually it would be a split second, but every so often it would be for quite some time).

Faulting

Fixed

So comfort and the rest of the lower dash stripped out and the wiring loom investigated. There was some questionable connections made and not by the customer, by a previous "pro" (red crimps on 0.35 and 0.5 wires and scotch locks comes on seriously). They where removed and replaced with solder, heat shrink (another new snap on toy! It's been an expensive week or 2) and the appropriate tape.

Eventually I found part of the main wiring harness leading towards the bulkhead had rubbed badly due to it not being secured where it once was. Access from the dash side was dire so wipers off and the big square blower blank/grommet removed for easier access. Found 5 wires had partial damage to the insulation these where repaired. 3 also turned out to be one of the PWM and dipped beam wires. These where repaired and the fault stopped. Van kept overnight for a day for monitoring purposes (this had me paranoid by this point) but the customer picked the vehicle up 26th May a d has said it hasn't faulted once!

I'd just like to say a MASSIVE thank you for everyone's input. It can be pretty lonely when you have a fault you can't get to the bottom of and know one else to consult with. Absolutely love this forum. There's probably some bits I've forgot to mention I'll update if anything springs to mind.

Cheers

Chris

Last edited:

Too marks for tenacity and not giving up. Glad you got this sortedUPDATE: It took a while but it's bloody FIXED!

Checked the battery as suggested ( I bought a new Snap-On toy...Erm I mean battery tester) and extensive investigation of the wiring loom in the engine bay/scuttle panel areas. Earth points stripped, cleaned and a couple added in as I wasn't convinced on one of the earths. It seemed to give some strange readings. I bought another toy... I mean tool a Picoscope 2204a Oscilloscope, the handheld is great for guidance but for the in depth nitty gritty this thing is ACE!

Picoscope connected up and found the PWM (Pulse Width Modulation) wires on both lights would fault when the lights blinked (couldn't captured this on the handheld as no record function). Admittedly it was a consistent signal when the light faulted but not how it should of looked. So connected one channel to PWM and then decided to track what the voltage to the dipped beam did during fault, to see if it was isolated to the PWM. It wasn't (pictures attached showing the fault when the light was off for around 6 seconds. Usually it would be a split second, but every so often it would be for quite some time).

So comfort and the rest of the lower dash stripped out and the wiring loom investigated. There was some questionable connections made and not by the customer, by a previous "pro" (red crimps on 0.35 and 0.5 wires and scotch locks comes on seriously). They where removed and replaced with solder, heat shrink (another new snap on toy! It's been an expensive week or 2) and the appropriate tape.

Eventually I found part of the main wiring harness leading towards the bulkhead had rubbed badly due to it not being secured where it once was. Access from the dash side was dire so wipers off and the big square blower blank/grommet removed for easier access. Found 5 wires had partial damage to the insulation these where repaired. 3 also turned out to be one of the PWM and dipped beam wires. These where repaired and the fault stopped. Van kept overnight for a day for monitoring purposes (this had me paranoid by this point) but the customer picked the vehicle up 26th May a d has said it hasn't faulted once!

I'd just like to say a MASSIVE thank you for everyone's input. It can be pretty lonely when you have a fault you can't get to the bottom of and know one else to consult with. Absolutely love this forum. There's probably some bits I've forgot to mention I'll update if anything springs to mind.

Cheers

Chris

Cheers pal I hate being beaten with faultsToo marks for tenacity and not giving up. Glad you got this sorted

Your not joking I much prefer install than diagnostics! However I'm really getting into the oscilloscope stuff since thisTracing electrical faults has to be one of the most difficult jobs on vehicles. Hats off to you for persevering and winning the battle.

Well done for not giving up and persevering.

Dont you find when you have a stinker of a fault and you solve it eventually, you have learnt heaps along the way which will come in handy another time.

Once again good effort.

Dont you find when you have a stinker of a fault and you solve it eventually, you have learnt heaps along the way which will come in handy another time.

Once again good effort.

Top result Chris !

Getting nervous about my scotchlocks now !

Getting nervous about my scotchlocks now !

Deleted Member

Account closed by request

I didn’t realise someone else had already been chopping the loom about, that’s usually the first place to look, but if you don’t know then it’s like pot luck.

Well done on your perseverance, hopefully you’ll get some contribution towards your fault finding costs as it wasn’t an issue you created?

Well done on your perseverance, hopefully you’ll get some contribution towards your fault finding costs as it wasn’t an issue you created?

Well done. Scotchlocs should be made illegal! Edited to say some insulation displacement connectors are fine eg for telephone wires.

I’ve watched a few ‘diagnose Dan’ videos on youtube. He always gets the difficult ones others cannot fix!

I’ve watched a few ‘diagnose Dan’ videos on youtube. He always gets the difficult ones others cannot fix!

Last edited:

You're not kidding mate. It'll all help later onWell done for not giving up and persevering.

Dont you find when you have a stinker of a fault and you solve it eventually, you have learnt heaps along the way which will come in handy another time.

Once again good effort.

Mate do yourself a favour in the long run. Sack them off do it properly with solder. They're a fault waiting to happen. I hate the bloody thingsTop result Chris !

Getting nervous about my scotchlocks now !

Similar threads

- Replies

- 26

- Views

- 788

- Replies

- 7

- Views

- 815

- Replies

- 0

- Views

- 199

- Replies

- 46

- Views

- 6K