Hi All,

Not sure if this is of use but I took a few pictures as I fitted my D2 diesel heater, may help people having a go themselves.

I’m not a pro at fitting these and this is the first I have done, any criticism is welcome.

For reference this is the underslung T6 specific kit and I’m fitting as part of my camper conversion on a 66plate euro 6 LWB highline 150.

So first job up on timber blocks rather than stands as I felt more comfortable that way for this.

So next all the panels off left and right underneath, these were already off for me as doing various bits beneath.

Next located the factory positions for rivnuts under drivers seat area.

Fitted two m6 rivnuts and test fitted bracket, stainless fixings used throughout as I’m a bit of a tart and don’t like rust.

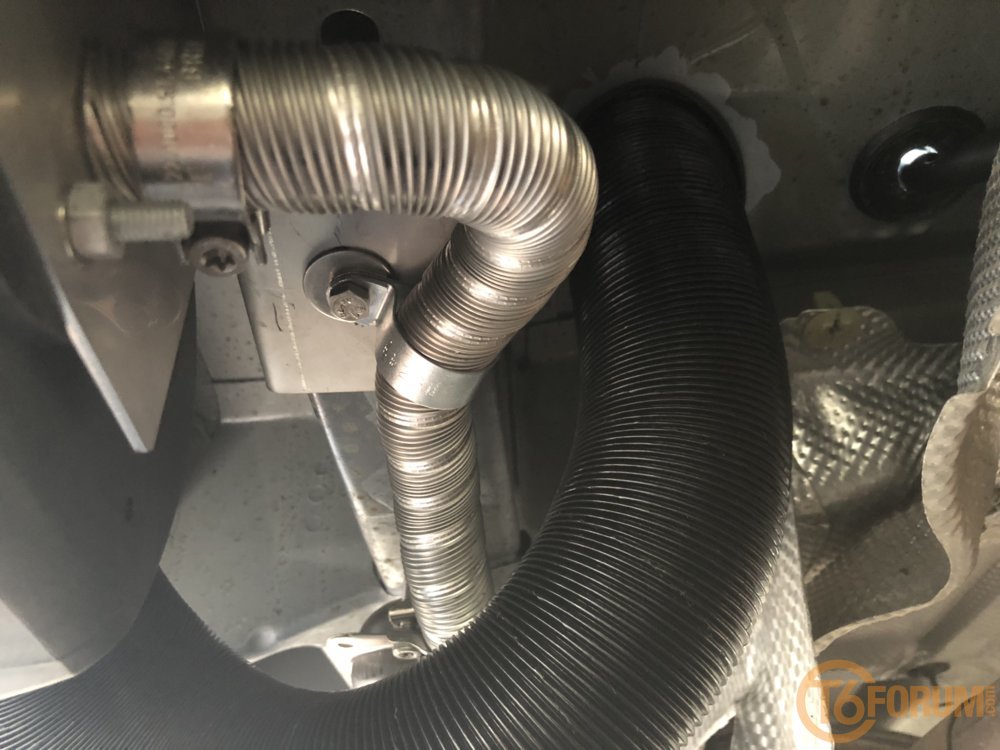

Fitted bracket to heater along with flexi pipe on high pressure side.

Bolted up and fitted high pressure line next, used rubber lined p clips to support. Used all factory holes with rivnuts for this, existing positions perfect. Then clipped along in spare point on existing clips towards tank.

Not sure if this is of use but I took a few pictures as I fitted my D2 diesel heater, may help people having a go themselves.

I’m not a pro at fitting these and this is the first I have done, any criticism is welcome.

For reference this is the underslung T6 specific kit and I’m fitting as part of my camper conversion on a 66plate euro 6 LWB highline 150.

So first job up on timber blocks rather than stands as I felt more comfortable that way for this.

So next all the panels off left and right underneath, these were already off for me as doing various bits beneath.

Next located the factory positions for rivnuts under drivers seat area.

Fitted two m6 rivnuts and test fitted bracket, stainless fixings used throughout as I’m a bit of a tart and don’t like rust.

Fitted bracket to heater along with flexi pipe on high pressure side.

Bolted up and fitted high pressure line next, used rubber lined p clips to support. Used all factory holes with rivnuts for this, existing positions perfect. Then clipped along in spare point on existing clips towards tank.

Last edited: