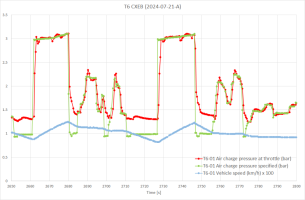

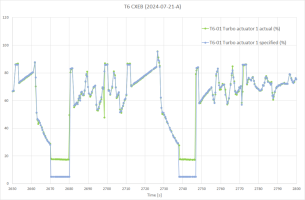

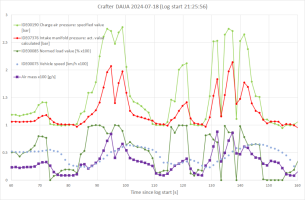

Mmi - some one has suggested fuel pressure sensor/ regulator issue to me, what parameters should I click to present a data log for this?

Could do with looking at fuel

Pressure and injectors I guess….

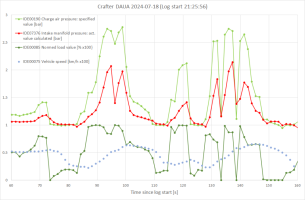

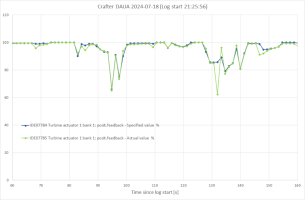

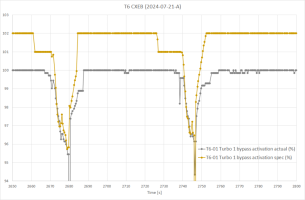

Allthough I have no codes to suggest a problem here, just still the underboost po299….

Been out again today, still doing it but less frequent since the oil flush/change.

Could do with looking at fuel

Pressure and injectors I guess….

Allthough I have no codes to suggest a problem here, just still the underboost po299….

Been out again today, still doing it but less frequent since the oil flush/change.