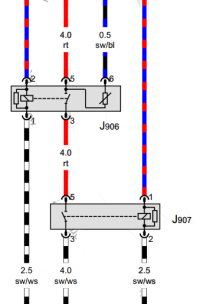

After checking some wire diagrams looks like the high current relay is in the starter itself and starter relays 1 and 2 in the ebox just provide feed for the starter solenoid but not the cranking power.

If I read diagrams right starter relays are driven by ECU in the ebox, and relay 2 (J907) output has an extra wire that goes to the ECU, BCM and voltage stabiliser. The symbol within relay looks kind of like a potentiometer but without control arm linked - I think this is the measurement wire.

Terminal 1 - GND

Terminal 2 - ECU

Terminal 5 - Starter solenoid

Terminal 3 - Starter relay 1

Terminal 6 - ECU, BCM and voltage stabilizer

View attachment 215495

Hmmm... for CAAC engine built before June 2018 I think the circuit is slightly different (wiring diagram No. 6/16)

The starter relay 2 (J907) does not have the extra wire to the ECU, etc.

Also black/white wires (from bottom) to the circuitry are from ignition switch terminal 15, thus +12V ignition on.

Just got curious about...Would @mmi have any insight into this?

Might be helpful - could you please make a couple of full blockmap capturesDo I need to do a blockmap capture

VCDS > Applications > Controller Channel Map

[Single Controller Address - 01]

[Measuring Values]

[CSV file]

The result file blockmap-01-... will be in folder C:\Ross-Tech\VCDS\Logs\...

2) engine running

3) engine stopped by Stop/Start

Curious what's available for this engine AND possibly even capture something to speculate about the bits vs. engine status (not started/running/stopped)