Here's another approach for T6 DIY enthusiasts - taking advantage of very popular Carista OBDII-reader device - combined with an Android app.

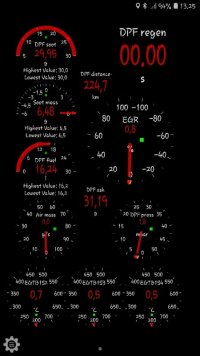

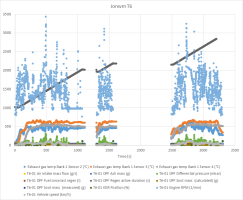

Most of the available meters are placed on a single page densely because this way the setup can be transferred reliably to other phones/tabs with different screen resolutions (by using attached setup file). Once intial setup is transferred everyone can remove/resize/reconstruct the view to match their own phone/tab preferences.

The measured parameters and their relevance will be explained later on..

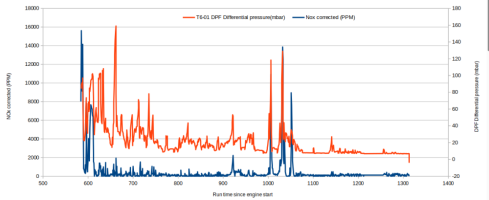

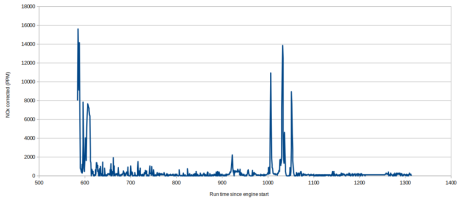

The log file contains a few more parameters than the display. Besides displayed also RPM, odometer and vehicle speed are recorded to make a proper log for later examination. To improve sampling rate slowly varying parameters are read only occasionally (e.g DPF ash mass read every 60 seconds, odometer every 30 seconds, Regen duration every 2 seconds).

The "boxed" values at the bottom are calculated based on actual log file (columns A-P)

NOTE: loading the setup file clears all Torque settings - it's a full restore. So before applying the attached setup, please use "backup all settings"-function to save your own settings.

Any comments/feedback/ideas?

Credit to @outcry666 and @n10n for inspiration and advices how-to unite T6 specific parameters with Torque Pro app

www.t6forum.com

www.t6forum.com

Ingredients:

- T6 EU6 engine: CXEB,CXEC,CXFA,CXGA,CXGB,CXGC,CXHA,CXHB.

- Carista OBDII device (also other generic OBDII (ELM327) devices will work)

- for alternative (faster) dongles see post #15 ---> [T6_measured] Monitoring DPF regeneration, DPF condition, EGR operation

- Android phone or tab

- Torque Pro app from Google Play Store (by the way, a £5 software from the UK)

- A setup file for T6 (attached) - almost plug and play to get the displays and data logging described below

Outcome 1:

Apologies about a bit disorganised view/screenshot below but this is just the initial/delivery setup.Most of the available meters are placed on a single page densely because this way the setup can be transferred reliably to other phones/tabs with different screen resolutions (by using attached setup file). Once intial setup is transferred everyone can remove/resize/reconstruct the view to match their own phone/tab preferences.

The measured parameters and their relevance will be explained later on..

Outcome 2:

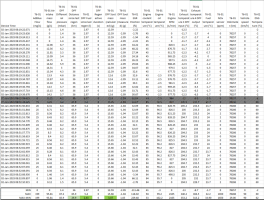

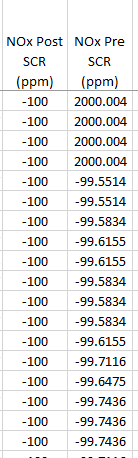

Here's just a snippet of a 53 second log file (only ignition on)The log file contains a few more parameters than the display. Besides displayed also RPM, odometer and vehicle speed are recorded to make a proper log for later examination. To improve sampling rate slowly varying parameters are read only occasionally (e.g DPF ash mass read every 60 seconds, odometer every 30 seconds, Regen duration every 2 seconds).

The "boxed" values at the bottom are calculated based on actual log file (columns A-P)

How-to get started:

- On your phone download attached setup file (20221218-B.zip.REMOVE.PLA) - most likely it will go to Downloads folder.

- NOTE: Naturally Torque (Android file handler) expects file with .zip extension - unfortunately the .zip-extension isn't allowed by Forum thus packaged here with .pla-extension - so please remove the .pla-extension.

- Plug in Carista device into T6 OBD diagnostics port

- Pair Carista dongle with your Android phone - if already paired with Carista that's already done

- Open Torque Pro - it will launch directly to "Realtime Information"/Dashboard view (as Outcome 1).

- Back up to Torque Main screen (below)

- Settings > Backup/Restore all settings > Restore all settings > look for the previously downloaded setup file "20221218-B.zip"

- Back up to Torque Main screen (above)

- Settings > OBD2 Adapter Settings > Choose Bluetooth Device > tick "Carista"

- Back up till you get to"Realtime Information"/Dashboard view

- Turn ignition ON

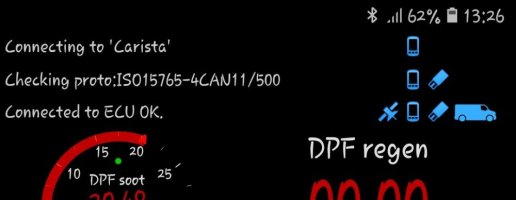

- Torque establishes communication with Carista, and subsequently with T6 ECU itself - the phases are indicated on top line as follows.

- Tweak individual meters by tap and hold

- > Move display - to move

- > Display configuration > Change size or Change display type, etc.

NOTE: loading the setup file clears all Torque settings - it's a full restore. So before applying the attached setup, please use "backup all settings"-function to save your own settings.

Any comments/feedback/ideas?

Credit to @outcry666 and @n10n for inspiration and advices how-to unite T6 specific parameters with Torque Pro app

VW T6 Custom PID codes for DPF

Hi, you know we cannot read DPF measurements by regular way. Only if you can see it with compatible OBD and the app called VAGDPF on Android based Head Units/Phones/Tablets. So, i want to share these Custom PID codes for using another apps like Torque OBD. You can use these codes for on any app...

Attachments

Last edited:

. Could you prepare a test case with and without grouping and instruct me on how to execute it? I'll then record / filter what's going on beyond the gateway and we can see if the actual UDS handling changes somehow.

. Could you prepare a test case with and without grouping and instruct me on how to execute it? I'll then record / filter what's going on beyond the gateway and we can see if the actual UDS handling changes somehow.