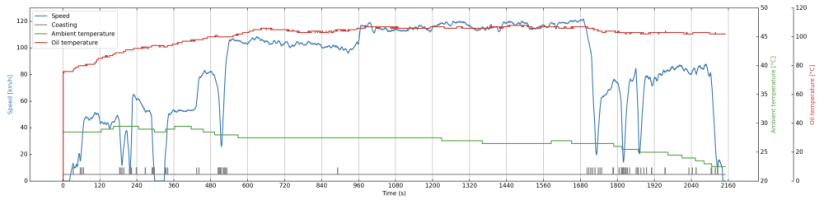

It's been a bit slow but finally got around testing plotting directly with Python and matplotlib library without R. Thanks for the tip regarding more than two axes @ebiii !

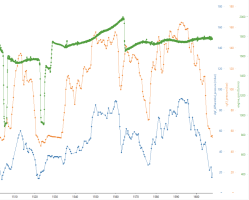

So, here's the above plot having everything in single plot instead of piling them up vertically.

And for anyone interested, here's the corresponding Python code:

So, here's the above plot having everything in single plot instead of piling them up vertically.

- Saves space

- Can get confusing with many signals

- Can't really use horizontal grid lines (or at least should use on main axis only)

- Discrete signals by scale + offset, no need for axis

- Although perhaps more confusing than piled style, there's still value as usually the danger of misinterpretation is low

And for anyone interested, here's the corresponding Python code:

Python:

import numpy as np

import pandas

import matplotlib.pyplot as plt

from mpl_toolkits.axes_grid1 import host_subplot

import mpl_toolkits.axisartist as AA

coasting = pandas.read_csv("hot.ChannelGroup_0_CAN1_-_message_dsg_10hz_0x359.csv")

speed = pandas.read_csv("hot.ChannelGroup_1_CAN1_-_message_kombi_1_40hz_0x320.csv")

ambient_temperature = pandas.read_csv("hot.ChannelGroup_2_CAN1_-_message_mfd_50hz_0x527.csv")

oil_temperature = pandas.read_csv("hot.ChannelGroup_3_CAN2_-_message_engine_7_50hz_0x588.csv")

df = pandas.merge(

pandas.merge(coasting, speed, on = 'timestamps'),

pandas.merge(ambient_temperature, oil_temperature, on = 'timestamps'),

on = 'timestamps'

)

df.rename(inplace = True, columns={

"CAN1.dsg_10hz.coasting": "coasting",

"CAN1.kombi_1_40hz.kombi_speed_actual": "speed",

"CAN1.mfd_50hz.ambient_temperature": "ambient_temperature",

"CAN2.engine_7_50hz.oil_temperature": "oil_temperature"

})

# Scale + offset coasting to main axis

df['coasting'] = df['coasting'] * 5 + 5

print(df)

fig = plt.figure()

plt.subplots_adjust(right = 0.75)

color = 'tab:blue'

r1c1ax1 = host_subplot(111, axes_class = AA.Axes)

r1c1ax1.set_xlabel('Time (s)')

r1c1ax1.set_ylabel('Speed [km/h]', color=color)

r1c1ax1.plot(df['timestamps'], df['speed'], color=color, label = 'Speed')

r1c1ax1.plot(df['timestamps'], df['coasting'], color='tab:gray', label = 'Coasting')

r1c1ax1.tick_params(axis='y', labelcolor=color)

r1c1ax1.set(ylim = (0, 130))

r1c1ax1.set_xticks(np.arange(0, 2200, 120))

r1c1ax1.grid(axis = 'x')

color = 'tab:green'

r1c1ax2 = r1c1ax1.twinx()

r1c1ax2.axis["right"].toggle(all=True)

r1c1ax2.set_ylabel('Ambient temperature [°C]', color=color)

r1c1ax2.plot(df['timestamps'], df['ambient_temperature'], color=color, label = 'Ambient temperature')

r1c1ax2.tick_params(axis='y', labelcolor=color)

r1c1ax2.set(ylim = (20, 50))

color = 'tab:red'

r1c1ax3 = r1c1ax1.twinx()

r1c1ax3.axis["right"].toggle(all=True)

r1c1ax3.axis['right'] = r1c1ax3.new_fixed_axis(loc = 'right', offset = (60, 0))

r1c1ax3.set_ylabel('Oil temperature [°C]', color=color)

r1c1ax3.plot(df['timestamps'], df['oil_temperature'], color=color, label = 'Oil temperature')

r1c1ax3.tick_params(axis='y', labelcolor=color)

r1c1ax3.set(ylim = (0, 120))

r1c1ax1.legend()

fig.tight_layout()

plt.show()